Matara has designed and built an XY linear system for Layton Technologies Ltd. capable of providing speed and precision accuracy for a PCB coating machine, that’s also able to endure corrosive atmospheres.

ABOUT: Layton Technologies Ltd.

Layton Technologies Ltd. is an international leader in the design and manufacture of machines for cleaning, drying, surface treatment and material recovery for precision cleaning applications. Its machines are used in every area of manufacturing for both semi-finished and finished products and their component parts. It designs and builds every type of machine, using both aqueous and solvent cleaning chemistries, with the majority of machines being completely bespoke.

THE REQUIREMENT: Linear motion system for PCB coating machine

THE REQUIREMENT: Linear motion system for PCB coating machine

Layton Technologies has extensive experience in the electronics sector, providing cleaning and drying solutions for Printed Circuit Boards (PCB), Hybrid Circuits, Surface Mount Technology (SMT) components, switches, resistors and capacitors. For one electronics customer, rapidly expanding their PCB manufacturing facilities in the UK, Layton was asked to develop a machine for conformal coating of PCBs.

Conformal coating is a special polymeric film forming product that protects circuit boards, components, and other electronic devices from adverse environmental conditions. The coating provides increased dielectric resistance, operational integrity, and protection from corrosive atmospheres, humidity, heat, fungus, and airborne contamination such as dirt and dust. It is applied either by spraying or, in this case, dipping the PCB into the solution.

Whilst the PCBs for this customer’s application are of the same type, they come in several sizes, so the machinery needs to adapt to this. Precision is vital due to the design of the PCB and to ensure the coating goes onto very specific parts of the PCB only and does not stray onto other areas. Furthermore, the machine needs to be highly reliable, as it is required to run continuously over an eight hour shift, coating approximately 50 PCBs per hour.

To achieve this, a linear motion system was required giving a smooth, precisely controlled XY motion in and out of the coating tanks.

THE SOLUTION: Matara XY linear system

At Matara, we have designed XY linear motion systems for incorporation into a huge variety of OEM machinery, including applications such as this presented by Layton Technologies where precision needs to be combined with durability.

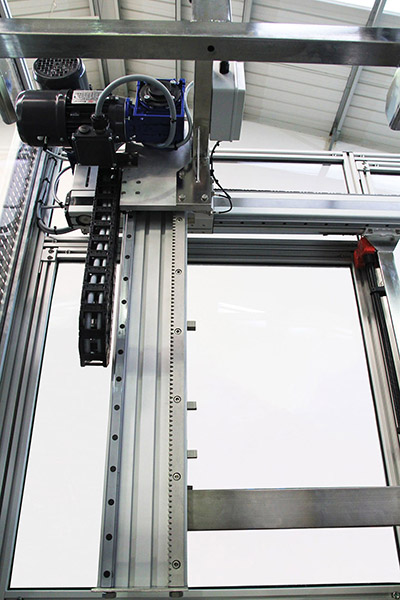

To achieve smooth and efficient movement, and avoid any spillages during operation, we selected an MTS Guided Belt Driven Actuator for the horizontal axis. Belt driven actuators perform better than ballscrew actuators at higher velocities and also in applications that require a long stroke, making it a suitable choice for this system. The MTS unit was particularly suited for this application due to its construction, which features an internal rail system and, externally, a rail and two carriages either side of the piston, providing a high degree of rigidity and accuracy. A MOD3 Stainless Rack & Pinion Actuator also forms part of the XY configuration, applied vertically. It is also rigid, can lift heavy loads and has a long 810mm stroke.

Contained within the workings of the machine is a second vertical application, consisting of a Matara MTV Ballscrew Driven Actuator size 65 x 620mm. This comes with a motor side drive and worm gear box with a 5:1 ratio.

We also supplied air preparation components as part of a pneumatic circuit on the machine. Products include MAR series pneumatic regulators, MAFR series pneumatic filter regulators, SVR series manifolds, and an MVSY 4 station manifold complete with pneumatic solenoid valves.

The entire linear motion system is enclosed by an aluminium framework, using 40×40 and 40×80 aluminium profile, with 5mm Polycarbonate sheets throughout, cut to size.

To withstand the harsh environment the machinery will be working in, which is subject to corrosive vapours from the coating process, stainless steel components have been chosen wherever possible and linear rails have been Armoloy TDC® coated. Armoloy TDC® coating is a hard (78Rc), thin, dense chromium coating with a micro-nodular surface texture, which provides corrosion protection equal to 440 series stainless steel.

The Matara XY linear system has been incorporated into Layton’s coating machine, where it is performing as expected and is able to meet the complexities of the process.

Commenting on the decision to award this project to Matara, Vikki Breese, Business Development Manager at Layton Technologies puts it down to the excellent working relationship the two companies have enjoyed: “Layton have collaborated successfully with Matara on many projects where precision, reliability and flexibility of handling system has been paramount to the success of the project. Furthermore, we have always found the service excellent.

Matara UK Ltd.

Tel: +44(0) 1684 850000

Fax: +44(0) 1684 850066

Email: sales@matarauk.co.uk